Understanding the Energy Efficiency of RV Worm Gear Reducers

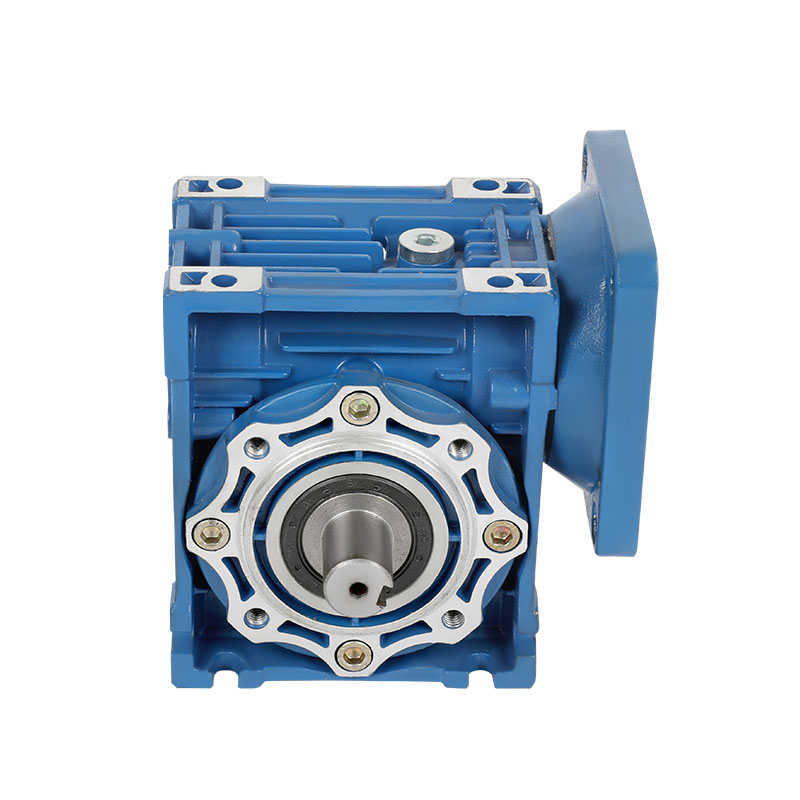

The RV Worm Gear Reducer is a compact and efficient power transmission device widely used in automation, robotics, conveyors, and heavy machinery. Its primary function is to reduce speed while increasing torque output, but one of its most compelling advantages lies in its energy efficiency. By integrating precision engineering with advanced material design, RV Worm Gear Reducers minimize energy loss during power transmission, making them a sustainable choice in modern mechanical systems.

Unlike traditional gear mechanisms, the RV Worm Gear Reducer combines the mechanical simplicity of worm gears with the precision of RV cycloidal structure, ensuring smooth operation and reduced energy waste. Understanding these energy-saving benefits helps engineers and manufacturers make informed decisions when optimizing systems for long-term performance and sustainability.

High Torque Density and Compact Design

One of the fundamental energy-saving features of an RV Worm Gear Reducer is its ability to deliver high torque density in a compact housing. High torque density means that less input energy is required to achieve the desired output torque. The precision-matched worm and wheel geometry ensures optimal load distribution, reducing the amount of frictional loss during power transfer.

The compact design minimizes rotational inertia, allowing motors to operate efficiently without overexertion. This leads to reduced energy consumption and less heat generation — a key factor for systems that run continuously. By lowering mechanical strain and maintaining torque stability, the RV Worm Gear Reducer effectively enhances overall energy performance.

Comparison of Torque Efficiency

| Gear Type | Torque Output Efficiency | Energy Consumption |

| Standard Worm Gear | Medium | Higher |

| RV Worm Gear Reducer | High | Lower |

| Planetary Reducer | Very High | Moderate |

Low Friction and Smooth Power Transmission

Friction is the major cause of energy loss in gear systems. The RV Worm Gear Reducer uses optimized tooth geometry and surface finishing to minimize sliding friction between the worm and the gear wheel. Unlike traditional worm drives that rely heavily on sliding motion, the RV mechanism utilizes rolling contact to improve efficiency and reduce energy loss.

Additionally, the use of high-grade lubricants and precise alignment reduces the energy wasted through heat and vibration. The smoother engagement between gear teeth translates into a quieter, cooler, and more stable operation — all of which contribute to lower energy consumption over time.

Key Design Features that Reduce Energy Loss

- Precision-ground worm threads to minimize micro-friction.

- High-efficiency lubrication system to reduce mechanical drag.

- Optimized tooth contact for smooth power transfer.

- Heat-resistant housing materials to prevent thermal deformation.

Reduced Heat Generation and Energy Waste

Excessive heat is one of the biggest inefficiencies in mechanical systems. Traditional worm gear reducers often suffer from high friction and subsequent energy loss in the form of heat. In contrast, the RV Worm Gear Reducer employs superior heat dissipation designs, ensuring that energy is effectively converted into mechanical output rather than wasted as thermal energy.

Improved housing ventilation, advanced lubricant formulations, and balanced torque distribution all contribute to lower heat buildup. This thermal stability not only saves energy but also prolongs the lifespan of the gears, bearings, and lubricants, reducing long-term maintenance costs and resource waste.

Thermal Efficiency Comparison

| Gear Reducer Type | Typical Heat Generation | Energy Efficiency Level |

| Traditional Worm Reducer | High | Low |

| RV Worm Gear Reducer | Low to Medium | High |

Optimized Power-to-Weight Ratio

The lightweight yet robust construction of RV Worm Gear Reducers plays a significant role in their energy efficiency. The optimized power-to-weight ratio reduces the load on the driving motor, allowing it to operate within its most efficient performance range. In industrial systems where energy costs are a major concern, reducing motor strain directly translates to reduced electricity consumption and improved operational sustainability.

By minimizing unnecessary mass and maximizing mechanical output, the RV Worm Gear Reducer provides an ideal balance of performance and efficiency, making it suitable for compact robotic joints, conveyors, and automation systems where energy economy is critical.

Maintenance Efficiency and Lifecycle Energy Savings

Energy savings do not only come from operation but also from reduced maintenance demands. The RV Worm Gear Reducer’s long service life and low maintenance requirements contribute to indirect energy savings over its lifecycle. With fewer replacements, less downtime, and reduced lubricant waste, the overall energy footprint of the system decreases significantly.

- Extended operational life reduces energy used in manufacturing replacements.

- Lower friction leads to longer lubricant intervals, saving resources.

- Minimal vibration ensures consistent motor efficiency.

- Reduced downtime enhances production energy utilization.

Sustainability and Environmental Impact

Energy efficiency in mechanical systems contributes directly to environmental sustainability. The RV Worm Gear Reducer aligns with global trends toward eco-friendly industrial design. By maximizing power transmission and minimizing energy loss, these reducers help lower CO₂ emissions and improve overall energy management across various sectors such as robotics, packaging, and logistics.

Manufacturers increasingly use recyclable materials, precision machining, and low-friction coatings in RV Worm Gear Reducers, further supporting green manufacturing initiatives. The combination of efficiency, durability, and sustainability positions the RV Worm Gear Reducer as a forward-looking solution for modern industries aiming to reduce their energy consumption footprint.

Conclusion: Efficiency Meets Reliability

The RV Worm Gear Reducer represents a perfect synergy between power transmission efficiency and energy conservation. Its high torque output, low friction design, optimized thermal performance, and long service life contribute to measurable energy savings in every application. As industries continue to prioritize sustainability and cost-efficiency, adopting RV Worm Gear Reducers offers not just operational benefits but also long-term environmental and financial advantages. In essence, every rotation saves energy — and every system becomes more sustainable.

English

English русский

русский bahasa Indonesia

bahasa Indonesia