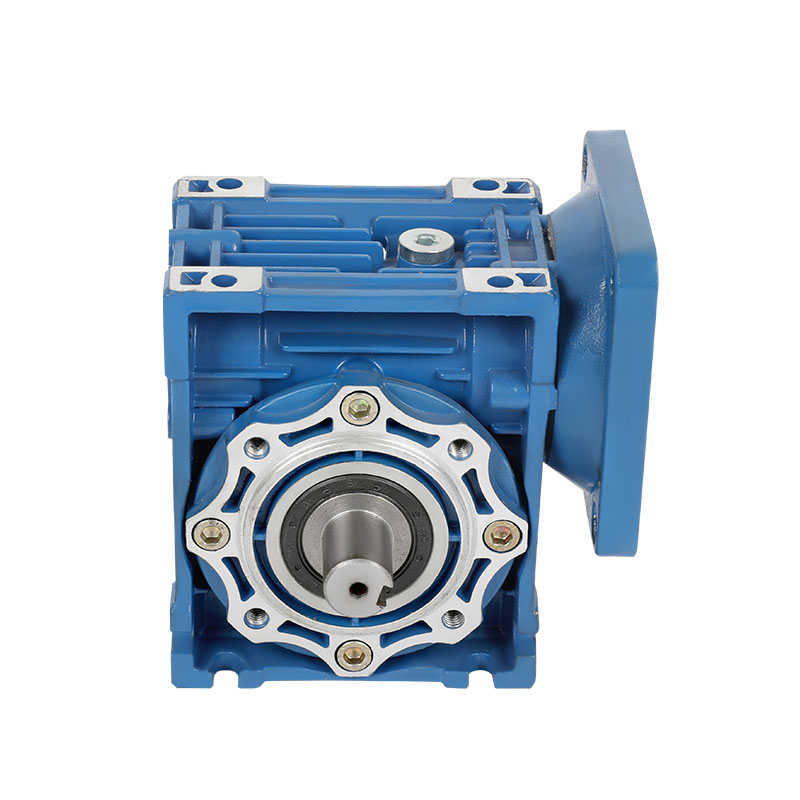

The RV worm gear reducer is a specialized type of speed reduction device that combines the benefits of worm gear technology with robust construction to deliver high torque output at reduced speeds. This mechanical component plays a crucial role in various industrial and commercial applications where precise speed control and high torque transmission are essential.

Primary Applications

Industrial Machinery

The RV worm gear reducer is extensively used in manufacturing equipment, conveyor systems, and assembly lines. Its ability to provide smooth, quiet operation makes it ideal for environments where noise reduction is important. The reducer's high reduction ratios allow machinery to operate at optimal speeds while maintaining the necessary torque for heavy-duty applications.

Material Handling Equipment

In the logistics and warehousing industry, RV worm gear reducers power conveyor belts, roller tables, and automated sorting systems. Their compact design and reliable performance make them perfect for continuous operation in demanding material handling environments where space efficiency and durability are paramount.

Construction and Mining

Heavy-duty construction equipment such as cranes, excavators, and mining machinery utilize RV worm gear reducers for their superior load-bearing capacity and resistance to shock loads. The reducer's ability to handle high torque applications while maintaining compact dimensions makes it invaluable in these rugged environments.

Automotive Industry

The automotive sector employs RV worm gear reducers in various applications, including power steering systems, windshield wiper mechanisms, and seat adjustment systems. Their precise control capabilities and compact size make them ideal for automotive applications where space constraints and reliability are critical factors.

Key Advantages

High Reduction Ratios

RV worm gear reducers can achieve reduction ratios ranging from 5:1 to 100:1 or higher in a single stage, making them extremely effective for applications requiring significant speed reduction and torque multiplication.

Compact Design

Despite their high torque capacity, these reducers maintain a relatively compact footprint, allowing for integration into space-constrained applications without compromising performance.

Smooth Operation

The worm gear design provides exceptionally smooth and quiet operation, reducing vibration and noise levels in sensitive environments such as medical equipment and precision instruments.

Self-Locking Capability

Many RV worm gear reducers offer self-locking properties, meaning they can hold loads in position without additional braking systems, providing inherent safety and stability in lifting and positioning applications.

Specialized Applications

Robotics and Automation

Modern robotics extensively utilize RV worm gear reducers in joint mechanisms and actuator systems. Their precise control, compact size, and high torque density make them ideal for robotic arms, automated guided vehicles (AGVs), and industrial automation systems.

Renewable Energy

Wind turbines and solar tracking systems incorporate RV worm gear reducers for their ability to handle varying loads and provide precise positioning control. The reducers' durability and reliability are essential in harsh outdoor environments where maintenance access may be limited.

Marine Applications

Marine equipment such as winches, anchor systems, and steering mechanisms benefit from RV worm gear reducers' corrosion resistance and ability to operate in harsh saltwater environments.

Food Processing

The food industry utilizes these reducers in mixing equipment, conveyor systems, and packaging machinery where hygiene standards require sealed, easy-to-clean components that can withstand frequent washdown procedures.

Technical Benefits

The RV worm gear reducer's design provides excellent shock load resistance, making it suitable for applications with frequent start-stop cycles or variable loading conditions. Its thermal stability ensures consistent performance across varying operating temperatures, while its lubrication system maintains optimal efficiency throughout extended operation periods.

In conclusion, the RV worm gear reducer serves as a versatile and reliable solution for countless applications across diverse industries, offering the perfect combination of high torque output, precise speed control, compact design, and long-term durability that modern industrial operations demand.

English

English русский

русский Indonesia

Indonesia