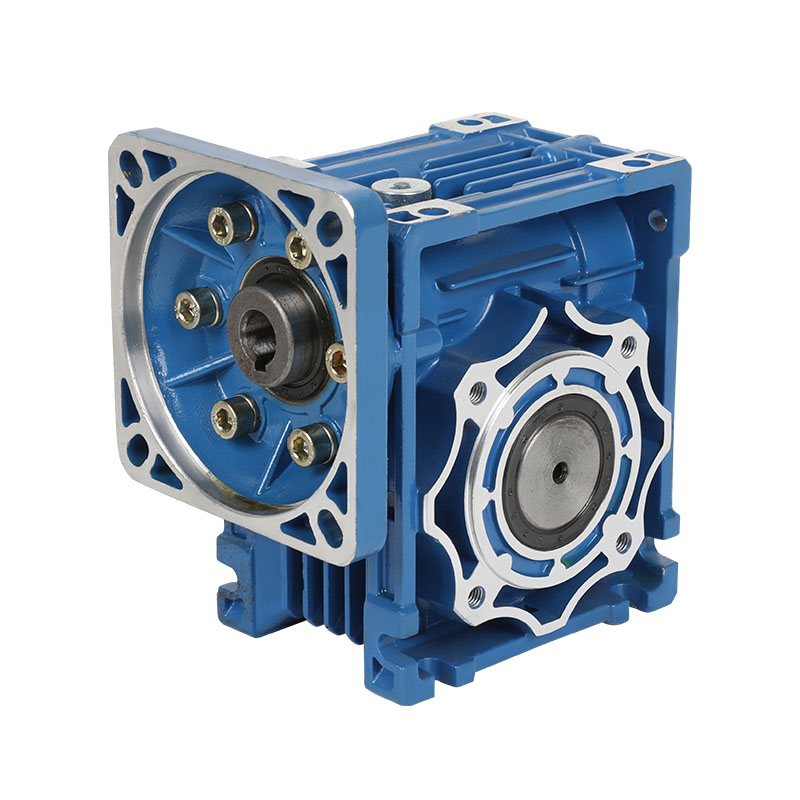

1. Introduction to RV Worm Gear Reducers

RV Worm Gear Reducers are widely used in mechanical systems to provide high reduction ratios in compact designs. Proper installation is crucial to maintain efficiency, extend service life, and prevent mechanical failures. Understanding key precautions before and during installation ensures that the reducer performs reliably under various operating conditions.

2. Site and Environment Preparation

Before installing the RV Worm Gear Reducer, it is important to prepare the site and ensure the surrounding environment is suitable for operation.

2.1 Clean and Level Surface

The mounting surface must be clean, flat, and free from debris. An uneven or dirty surface can cause misalignment, leading to excessive wear or premature failure of the gear reducer.

2.2 Environmental Conditions

Ensure that the installation environment is dry, well-ventilated, and free from corrosive chemicals or excessive dust. Exposure to moisture or harsh chemicals can degrade seals, bearings, and lubricants.

3. Mounting Precautions

Correct mounting is essential for optimal performance of the RV Worm Gear Reducer. Improper mounting can cause vibration, noise, or mechanical failure.

3.1 Alignment of Shafts

Ensure precise alignment between the input and output shafts. Misalignment can increase load on bearings and the worm gear, reducing efficiency and lifespan.

3.2 Secure Fastening

Use appropriate bolts and torque specifications to secure the reducer to the mounting surface. Loose fasteners can cause vibration and damage to internal components.

3.3 Base Support

The reducer should be mounted on a rigid support to minimize deformation under load. Flexible or weak bases can lead to misalignment and reduce the efficiency of power transmission.

4. Lubrication Considerations

Proper lubrication is critical for reducing friction, heat, and wear in the worm gear reducer.

4.1 Choosing the Right Lubricant

Use the lubricant recommended by the manufacturer. The viscosity and type of oil should match operating temperature and load conditions to ensure smooth gear operation.

4.2 Filling and Checking Oil Levels

Before operation, fill the reducer to the specified oil level. Overfilling or underfilling can cause overheating, oil leakage, or insufficient lubrication.

4.3 Periodic Maintenance

Regularly inspect oil levels, quality, and signs of contamination. Replace lubricant according to manufacturer schedules to maintain optimal performance.

5. Operational Precautions

After installation, certain operational practices should be observed to protect the reducer.

5.1 Gradual Loading

Avoid applying full load immediately. Start the system gradually to allow proper seating of components and to prevent sudden stress on the gears.

5.2 Temperature Monitoring

Monitor the operating temperature during initial hours. Excessive heat may indicate misalignment, improper lubrication, or overloading.

5.3 Vibration and Noise Checks

Listen for unusual noise or vibration. These may signal mounting issues, gear defects, or inadequate lubrication, which require immediate attention.

6. Conclusion

Proper installation of RV Worm Gear Reducers is essential for achieving efficient, reliable, and long-lasting performance. Key precautions include preparing a clean and level site, ensuring proper shaft alignment, securing the reducer firmly, and maintaining correct lubrication. Following these guidelines helps prevent mechanical failures, reduces maintenance costs, and extends the operational life of the reducer in various industrial applications.

English

English русский

русский bahasa Indonesia

bahasa Indonesia