WP worm gear reducers are mechanical devices designed to reduce motor speed while increasing torque output. They are widely used in industrial machinery, conveyors, and automation systems due to their compact structure, high load capacity, and efficiency in power transmission. By converting high-speed input into controlled low-speed output, worm gear reducers help optimize mechanical performance in a variety of applications.

This article explores WP worm gear reducers, including their working principles, types, advantages, selection criteria, installation practices, and maintenance tips for optimal industrial performance.

Understanding the WP Worm Gear Reducer

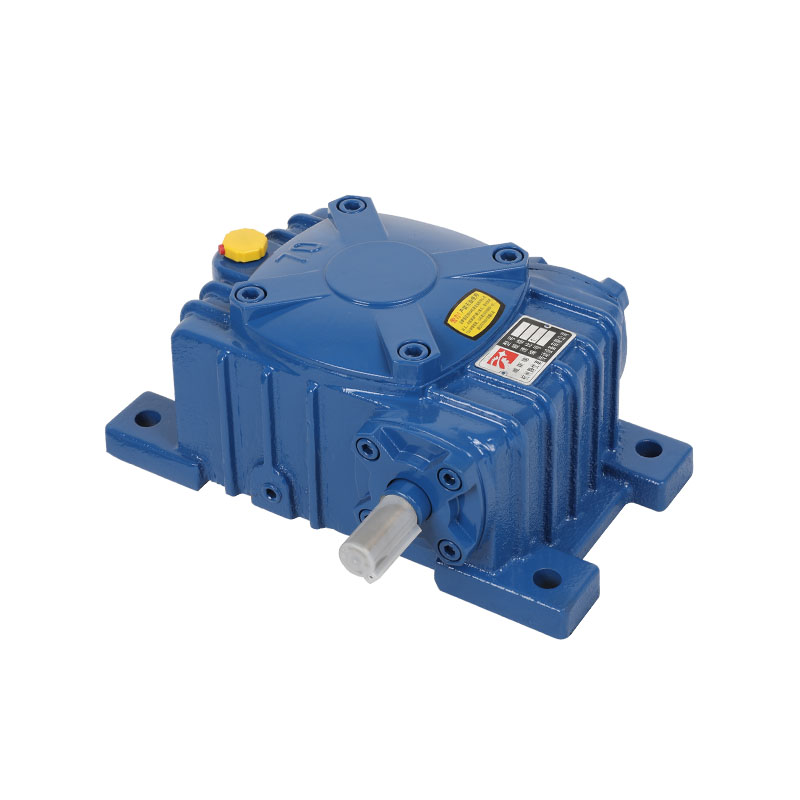

A WP worm gear reducer consists of a worm (screw) and a worm wheel (gear), enclosed within a robust housing. The worm engages the teeth of the worm wheel, transferring motion at a reduced speed while increasing torque. This mechanism allows smooth and quiet operation, making it suitable for precise industrial applications.

Key Components

- Worm Shaft: A threaded screw that meshes with the worm wheel to transmit motion.

- Worm Wheel: A gear wheel with teeth shaped to match the worm thread for efficient torque transfer.

- Housing: Encloses and protects the gear components, often made of cast iron or aluminum.

- Bearing System: Supports the worm and worm wheel for smooth operation.

- Lubrication System: Ensures minimal friction and heat generation during operation.

Working Principle of WP Worm Gear Reducers

WP worm gear reducers operate based on the meshing of the worm and worm wheel. When the worm rotates, its helical threads engage the teeth of the worm wheel, causing the wheel to turn at a slower speed. The reduction ratio is determined by the number of teeth on the worm wheel and the number of starts (threads) on the worm shaft.

This design enables high torque output even at low speeds, making it ideal for applications where precise motion control and torque multiplication are required.

Reduction Ratio Calculation

The reduction ratio can be calculated using the formula:

Reduction Ratio = Number of Teeth on Worm Wheel / Number of Starts on Worm

For example, a worm with a single start engaging a 40-tooth worm wheel achieves a 40:1 reduction, meaning the output shaft rotates once for every 40 rotations of the input shaft.

Types of WP Worm Gear Reducers

WP worm gear reducers come in various configurations, designed to meet different industrial needs and load requirements.

| Type | Features | Typical Applications |

|---|---|---|

| Single-Stage Worm Reducer | Compact design, suitable for moderate torque requirements, quiet operation | Conveyors, packaging machines, small industrial equipment |

| Multi-Stage Worm Reducer | Higher reduction ratios, capable of handling higher torque | Heavy machinery, cranes, elevators |

| Flange-Mounted Worm Reducer | Allows easy connection to motors and equipment, reduces space usage | Automated assembly lines, industrial mixers |

| Foot-Mounted Worm Reducer | Provides stability and flexibility for installation, standard output shaft options | Pumps, conveyors, packaging machines |

Advantages of WP Worm Gear Reducers

WP worm gear reducers offer several benefits that make them suitable for a wide range of industrial applications.

1. High Torque Output

Worm reducers can achieve large reduction ratios in a compact design, providing high torque output without requiring additional stages or components.

2. Compact and Space-Saving Design

The axial arrangement of the worm and worm wheel allows for a smaller footprint compared to other gear types, making them ideal for applications with limited space.

3. Smooth and Quiet Operation

The continuous sliding contact between the worm and wheel reduces vibration and noise, making WP worm gear reducers suitable for environments where low noise is essential.

4. Self-Locking Capability

Many WP worm gear reducers have inherent self-locking properties, preventing reverse motion of the output shaft under load. This feature is advantageous in lifting, hoisting, or positioning applications.

5. Versatility and Reliability

WP worm gear reducers are compatible with various industrial equipment, including conveyors, mixers, elevators, packaging machines, and heavy-duty machinery. Their robust construction ensures long service life and minimal maintenance.

Applications of WP Worm Gear Reducers

WP worm gear reducers are widely used across industries due to their high torque capacity, reliability, and compact design.

Industrial Machinery

Used in conveyor systems, automated assembly lines, and packaging equipment, WP worm gear reducers provide controlled speed reduction and consistent torque output.

Material Handling

Elevators, hoists, and cranes often rely on worm reducers for smooth and precise motion, thanks to their self-locking capability and high torque performance.

Mixing and Processing Equipment

Industrial mixers, kneaders, and extruders utilize worm gear reducers to achieve slow, consistent mixing with high torque, essential for material processing.

Selection Criteria for WP Worm Gear Reducers

Choosing the correct WP worm gear reducer requires careful consideration of operational requirements, environmental conditions, and performance needs.

Key Selection Factors

- Load and Torque Requirements: Determine the required output torque and ensure the reducer can handle peak and continuous loads.

- Reduction Ratio: Select a ratio that achieves desired speed and torque balance.

- Installation Orientation: Consider space constraints and motor connection type (flange or foot-mounted).

- Operating Environment: Evaluate exposure to dust, moisture, temperature extremes, and corrosive conditions.

- Maintenance and Lubrication: Choose reducers with easy lubrication access and minimal maintenance requirements.

Installation and Maintenance Tips

Installation Practices

- Ensure proper alignment of input and output shafts to prevent uneven wear.

- Secure the reducer to a stable mounting surface to avoid vibration.

- Check lubrication levels before operation and use recommended oils or greases.

- Verify reduction ratio and torque specifications match the system requirements.

Maintenance Recommendations

- Regularly inspect for wear on the worm and wheel teeth.

- Replace lubricants periodically to maintain smooth operation and reduce friction.

- Check for unusual noise or vibration as indicators of potential mechanical issues.

- Ensure that temperature remains within recommended limits to prevent overheating.

Conclusion

WP worm gear reducers are reliable, compact, and efficient devices for industrial speed reduction and torque multiplication. Their advantages, including high torque output, self-locking capability, quiet operation, and versatility, make them essential in modern machinery and automation systems. By understanding their working principle, types, selection criteria, and maintenance practices, industries can ensure optimal performance, long service life, and safe operation of their mechanical equipment.

English

English русский

русский bahasa Indonesia

bahasa Indonesia